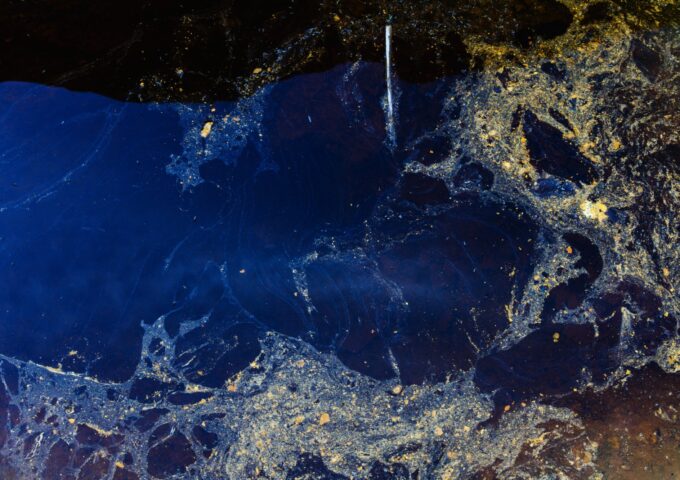

Harnessing the power of Microbes to Combat Pollutants

At Probiosphere, we understand the pressing need to address pollutants and their impact on our environment. Our innovative solutions provide effective measures to combat and eliminate pollutants, safeguarding ecosystems and promoting cleaner surroundings.

With our cutting-edge biotechnology, we tackle a wide range of pollutants, including organic contaminants, heavy metals, and harmful chemicals. With a focus on sustainability and natural processes, we offer tailored remediation solutions that reduce the ecological footprint while ensuring optimal results.

FAQ

Searching for answers? We’re here to assist!

Heavy metals in water pose a serious environmental threat because of their soluble ionic forms. At Probiosphere, we master the science of electron transfer through bacterial activities. We use this biotechnology expertise to facilitate an oxidative or reductive environment.

Sulfate can be effectively removed from water through biological treatment methods. By employing specialized bacteria, Probiosphere harnesses biotechnological processes to facilitate sulfate reduction, resulting in the removal of sulfate ions from water sources, ensuring cleaner and safer water for various applications.

Nitrate can be removed from water through biological treatment techniques. Probiosphere utilizes specialized bacteria to facilitate denitrification, converting nitrate into harmless nitrogen gas. This natural process effectively reduces nitrate levels in water, ensuring the purity and safety of water sources for various purposes.

Cyanide can be effectively removed from water through biological treatment methods. Probiosphere employs specialized bacteria that utilize enzymatic reactions to degrade and detoxify cyanide, rendering it harmless. This natural approach ensures the removal of cyanide contaminants, safeguarding water quality and environmental well-being.

Phosphorus can be effectively removed from water through biological treatment methods in integrated sludge management systems. In smaller systems without biological sludge management, diverse physicochemical methods such as coagulation/flocculation exist. Probiosphere employs innovative technologies such as L2PR (Low Level Phosphorus Removal) that significantly reduce phosphorus concentrations, preventing eutrophication and promoting sustainable water and wastewater treatment practises.

Phosphorus can be effectively removed from water through biological treatment methods in integrated sludge management systems. In smaller systems without biological sludge management, diverse physicochemical methods such as coagulation/flocculation exist. Probiosphere employs innovative technologies such as L2PR (Low Level Phosphorus Removal) that significantly reduce phosphorus concentrations, preventing eutrophication and promoting sustainable water and wastewater treatment practices.

Let’s Work Together

At Probiosphere, we believe in the power of collaboration to drive meaningful change. Join us in our mission to create a sustainable future by working together. Whether you are a municipality, a business, or an organization facing environmental challenges, we offer tailored biotechnology remediation solutions to address your specific needs. Together, we can design and implement innovative solutions that not only mitigate environmental impacts but also contribute to lower carbon footprints and promote eco-friendly practices